Today more than 80 percent of vehicles on the road are equipped with air conditioning, but that wasn’t always the case. In this Blog I will be discussing some of the vehicles that I feel had the biggest impact on the vehicle industry throughout the 1940’s and 1950’s. In 1940, Packard Motorcar Company was the first to offer a factory installed air conditioning unit. The company that manufactured them was Bishop and Babcock Co, of Cleveland Ohio. The system had an evaporator, which at the time was called a “cooling coil,” and was located in the trunk. This system also didn’t have a compressor clutch, so whenever the engine was running, the pump was on. This first design was unsuccessful for a few reasons. Firstly, the main evaporator and blower system took up most of the trunk space. It had no temperature control switch for the blower, therefore, the driver had to get out of the vehicle and take the belt off to stop the compressor. Moreover, the cost of this system was $274.00 (roughly $4,591 today). This system was discontinued in 1941. There where a few other similarly designed air conditioning, manufactured by Cadillac and Chrysler through the early 1940’s, but nothing to note until 12 years later in 1953.

In 1953, General Motors, Packard, and Chrysler all designed a new air conditioning system. I will discuss the Chrysler Imperial’s Airtemp, because I believe this model was the first efficient air conditioning system for vehicles. It was the first vehicle that had recirculating air conditioning (known to us today as MAX AC) and the first to have a master control system with three fan settings—low, medium, and high—mounted directly on the dashboard. It featured duct doors, which directed airflow to the ceiling of the car, where it filtered down around the passengers instead of blowing directly on them. (This feature is no longer available in modern cars today.) This new and improved air conditioning system was capable of cooling the vehicle from 120 degrees to 85 degrees in about three minutes, while at the same time removing humidity, dust, pollen, and tobacco smoke from the vehicle. There where approximately 29,000 cars manufactured with air conditioning in 1953.

The Harrison Radiator division of General Motors can be credited with the first efficient, affordable air conditioning unit that was mass-produced. It was an available option add-on to all 1954 Pontiacs with v8 engines. It featured a bronze condenser and a two-cylinder reciprocating clutch compressor. It was the first system to have a magnetic clutch, which disengaged when the compressor was not in use, thus improving engine performance and fuel mileage.

I believe the next major event in air conditioning history was in 1957, when the Cadillac Eldorado Broughams set the standard for most cars today, and became the first car to have air conditioning as a standard item. Up until this point, air conditioning was considered a luxury, only available to wealthy car owners. In 1957, the American Motor Company concentrated on a new economical Rambler line, with the total cost of a car being as low as $2000.

Throughout the 1960’s, air conditioning installment in vehicles really took off. Including after market installed units and manufacture-installed units, 54% of vehicles contained air conditioning by 1969. Through the 70’s, 80’s, and early 90’s air conditioning manufacturing continued to grow rapidly, until the debate about the negative effects of the R-12 Freon on the ozone layer began. In 1995, the Montreal Protocol Act was implemented and the production of R-12 refrigerant was stopped in all vehicles. At this time, all manufacturers began using less harmful R-134A, which is still used today.

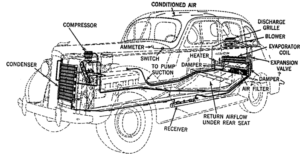

In order to fully appreciate how far the air conditioning in vehicles has come since Packard’s first system, which took up half of the trunk space in a vehicle, it is necessary to understand its basic set up today. The system has essentially run on the same 3 components since its invention: the compressor, condenser, and evaporator. The compressor is a pump that is driven by a belt mounted to the engine’s crankshaft. Its purpose is to compress the low-pressure vapor that enters it, turning it into a high-pressure vapor. The condenser is very similar to a radiator. Its job is to convert the high-pressure vapor into a liquid by removing the heat from the refrigerant as air passes through it. The evaporator is located in the dust work of the vehicle, unlike the previous two components, which are located under the hood. The evaporator’s job is to turn the high pressure liquid into a low-pressure vapor. At this point the blower motor, which is usually attached to the evaporator, blows cool air into the vehicle.

There are many more components in the air conditioning system in cars today, including a metering device, dust work, heater core, etc. I don’t feel it’s important to go into detail about all of them in order to understand the major accomplishments of the vehicle air conditioning industry in the last 75 years. Over all, it is truly amazing that the motor vehicle industry has moved so far from the original system, which had no control elements, was very large, and very expensive. In comparison, the system today is basically a standard for all vehicles bought from the manufacturer. It is made up of just a few components and hoses under the hood, and is so compact that most people don’t even notice it unless they know its there. It enables extremely accurate climate control, and can cool a vehicle to about 40 degrees, or heat it to over 100, at the will of the driver.

-Rextech

References

Adler, Dennis. “Packard.” Google Books. N.p., n.d. Web. 20 Mar. 2014.

Gardetto, Robert. “A Brief History of Chrysler Airtemp.” A Brief History of Chrysler Airtemp. N.p., n.d. Web. 20 Mar. 2014.

http://www.allpar.com/corporate/airtemp.php

Hall-geisler, Kristen. “How Automotive Air Conditioning Works.”

HowStuffWorks. N.p., n.d. Web. 21 Mar. 2014.

http://auto.howstuffworks.com/automotive-air-conditioning2.htm